whereas a traditional beret is made of one singular piece and the usual material would be felt or wool, the Gilboa Beret is made up of 10 individually and differently shaped pieces, giving the beret a voluminous and so some individuals have commented: a regal feel.

The completed piece - Gilboa Beret made with a rusty red cotton velvet. Detailing with pheasant and turkey feathers and antique buttons. Photograph has been taken with natural lighting which shows the beautiful colours of the feathers contrasting with the velvet. A great colour combination for this season.

I had a vague idea in my head regarding the design of the beret although the fabric thickness and handleability have to be taken into consideration and often require slight changes. I had already made up my mind what fabric I would want to work with:

A very lush rusty red velvet.

The previously sketched pin-tuck design is being transferred onto the reverse side of the velvet.

Barely visible, the transferred design in yellow dots on the reverse side of the velvet.

The pin-tucks are stitched on the right side of the fabric therefore I do now have to trace the dotted lines with baste stitching so that the design becomes visible on the right side of the velvet.

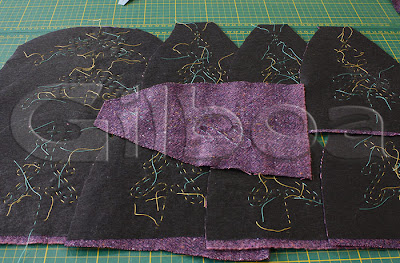

This has to be done x10 ... I also need to take into consideration that the pin-tucks will shrink and distort the fabric slightly so I have to carefully consider were to place the markers so that I can later cut the actual pieces before joining it all together. As you can see, all 10 pieces are cut extra large to compensate for the distortion caused by the pin-tucks.

The above image shows two stages: the pin-tucks are being stitched by following the basted stitching.

Again x10 ... Each swirly line needs to be cleaned up on the reverse so that the threads do not come loose later. It is a very time consuming effort and it is at this stage where sometimes I can change my mind and start all over again if the created effect is not to my liking.

The individual pieces have been cut into their individual shapes and the beret is slowly taking on shape.

It is during this stage when I decide whether I am indeed satisfied with the design ...

... the beret is slowly coming together. Before joining the two halves I insert a middle lining (again made with 10 individually shaped pieces) which will allow the wearer of the beret to be shape the hat to requirements.

Before adding the lining I select the feathers and buttons for detailing at the back and front.

The inner lining: a luxurious silk fabric which will keep your head comfortably warm. It is also made of 10 individually shaped pieces, just like the outer part of the beret.

And lastly: all pieces are ready to be joined together:

- the main part (velvet) is ready and fitted with 'shaping' lining

- the inner lining is also ready

- the decoration for the front and back have been hand sewn and are ready to be attached

Very often by the time I have completed a piece as detailed as this I have had enough of looking at it and am incabable of objectively judge its 'beauty'. I have to store it out of sight immediately but just before I leave the studio in the evening, I display it on the bust on the centre of my cutting table so that when I enter the next morning it will be the first thing I see; that is generally the moment when I make up my mind for the last time and decide whether it was worth all the effort.

In this case I very much like the end result and would have liked to keep it for myself ... but I deliberately made it too big for me so that I am not tempted.

I hope it will find a proud wearer!